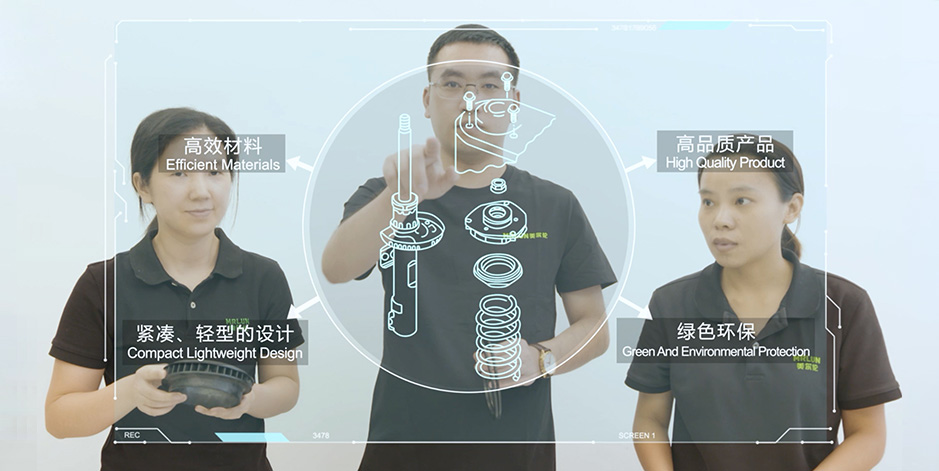

YUHUAN MRLUN MACHINERY CO., LTD. was establised in 2009, and professionally for developing and producing automobile McPherson suspension strut bearing

The main equipments are: precision stamping machine, high precision CNC machine, high-end injection molding machine, automatic assembly line, high precision testing equipment and testing equipment, with more than 200 sets

Certification: IATF16949:2016、ISO14001:2015、ISO45001:2018

Invention patent: over 20

Annual capacity: 15 million sets

Employee: over 140, research and development with 25, quality management with 20

Marketing network: export to over 60 countries and areas and over 20 provinces in mainland.

We have perfect management system and perfect quality control

Our products cover the mainstream market structure

We have a professional R&D team to support customized development

We have high-precision production and testing equipment to ensure the product quality

The technical center is mainly responsible for the research and development of new products for suspension bearings, as well as the updating and upgrading of old products、The research and application of technology validation、processing technology &mold fixture testing technology、detection product performance testing technology,、metal materials and heat treatment technology,it's the core department of the company's process、 research 、technical standards etc.

Strive for profit, Strive for development, Attach importance to scientific research,continuously creative, observe law and discipline, Maintain reputation, make no exception, happy work, environment protection, Benefit the community

Quality first, reputation first, management first, and service sincere.

Comply with compliance obligations applicable to environment, occupational health and safety, protect environment and reduce occupational health and safety risks;Strengthen the environmental protection, occupational health and safety awareness of all employees, and create a new modern enterprise image

The unremitting pursuit of quality, unswerving faith in technology, adherence to business ethics, fearless response to changes, and responsible for employees

The talent concept is:Achieve people with career, unite people with culture, and standardize people with system!

Achieve people with career:The broad development prospect of MRLUN attracts a large number of talents who are willing to make a career, and provides them with a career platform to play freely and a broad development space .The enterprises and individuals will grow together through joint efforts,so as to achieve the goal of retaining people and achieve people with career.

Unite people with culture:gathering people will make flourish of culture:cooperation form unique charm Mrlun enterprise culture, the culture attract employees, condensed staff to promote the development of Mrlun.

Standardize people with system:Take the system to regulate the behavior of employees and work procedures,Institutionalization and standardization are the foundation of enterprise operation and management, as well as the necessary conditions and foundation for the growth of MRLUN.

In the process of development, we have always maintained a harmonious coexistence with the ecological environment. From the selection of raw materials to the innovation of production processes, we have always insist the concept of environmental protection through every process of R&D and production to build a sustainable environmental protection enterprise.